From Historical Origins to Modern Day Innovations

The Origins of Land Rolling

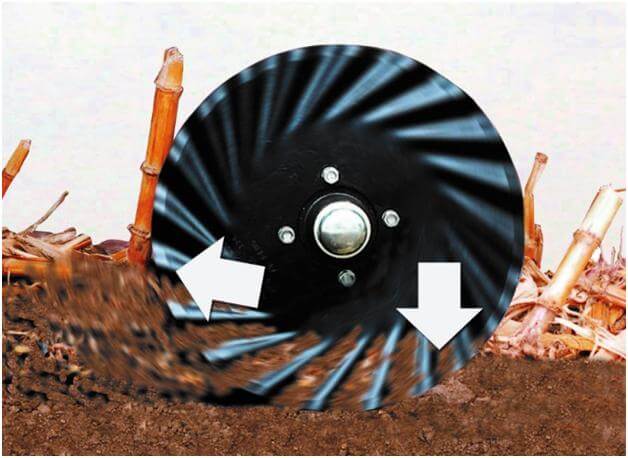

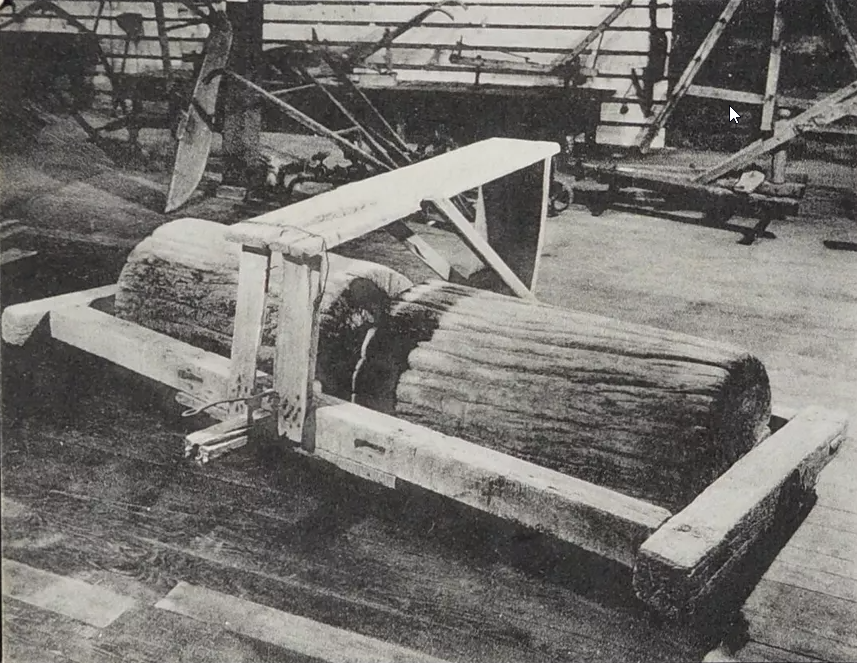

Dipping into antiquity, we find the early incarnations of land rollers. Farmers employed hefty stones or sturdy logs to even out their fields. This rudimentary approach was not merely about flattening; it was crucial. It helped break soil clods, enhance seed-to-soil contact, and achieve a uniform planting bed. As agriculture’s demands morphed, so did the sophistication of these tools.

Industrial Age Innovations

The 19th century’s industrial revelry, marked notably by the introduction of steam-powered machinery, heralded a new epoch in farming. The era saw the emergence of cast iron rollers, some adorned with teeth or smooth surfaces, designed to compact soil meticulously, curb water wastage, and bolster crop emergence. Yet, these contraptions, albeit revolutionary, were somewhat rigid and lacked the adaptability required for diverse agricultural needs.

Advancements in the Wake of the Industrial Revolution

The narrative of land rollers is further enriched as we stride into the industrial revolution’s later stages. Innovations in material science and manufacturing processes catalyzed the evolution of more dynamic land rollers. By the dawn of the 20th century, steel had largely supplanted cast iron, enhancing both durability and operational efficiency. The integration of adjustable widths and hydraulic mechanisms afforded farmers unprecedented flexibility, enabling precise adaptations to varied field conditions.

The Evolution and Endurance of Land Rollers

Land rollers have been an integral component of agricultural practices since at least the mid-19th century. These vital tools, designed to compact soil and smooth out fields post-seeding, showcase a fascinating evolution in farming technology.Initially made from natural resources like tree trunks, chosen for their durability and accessibility, these rollers showcase a time when local craftsmanship utilized available materials to fulfill farming needs. This use of organic materials highlights the resourcefulness of early agricultural methods. As agricultural technologies advanced, so did the design of land rollers, evolving from simple, manually-operated devices to more complex machinery. Despite these advancements, the core purpose of land rollers in aiding crop cultivation has steadfastly remained the same.

We also recommend you read our article: Why do Farmers Use Land Rollers?

Evolution of Land Roller Manufacturing Technology

The Origins of Land Rollers

In eras gone by, land rollers were basic contraptions, pieced together from natural materials such as wood and stone readily found in the environment. Wood, while malleable and relatively easy to manipulate, fell prey to degradation from the elements. Conversely, stone, with its robustness, presented logistical challenges due to its hefty nature and inflexible shape, which impeded its adaptability across diverse landscapes.

The Industrial Revolution: A New Era for Land Rollers

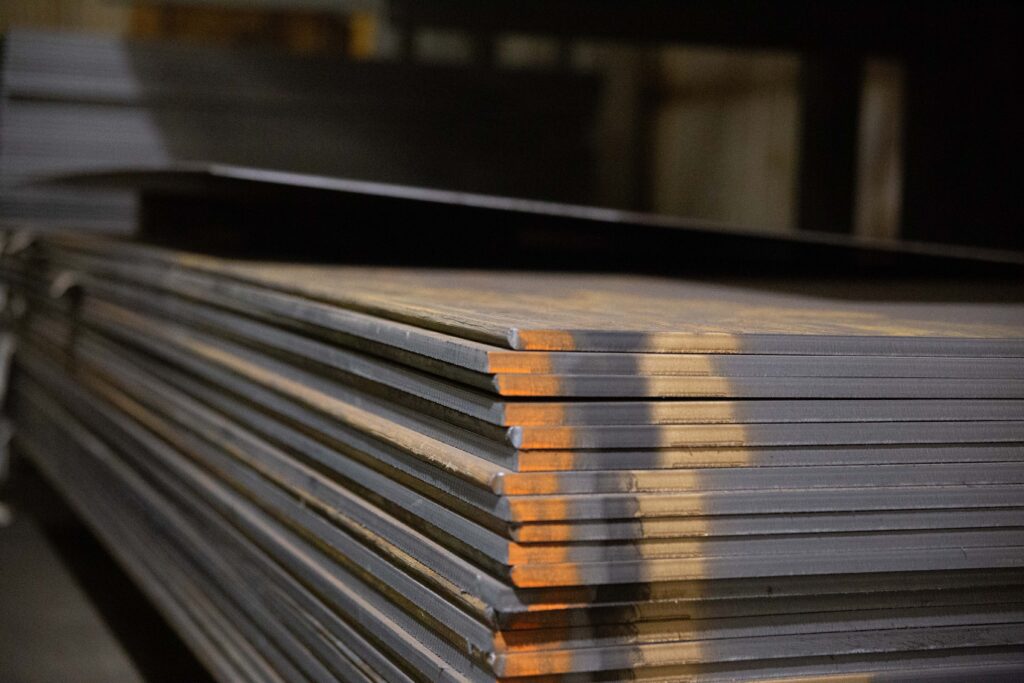

With the dawn of industrialization, a transformative phase began with the integration of metals like iron and steel into land roller fabrication. This transition was not merely a leap in durability but also a revolution in engineering precision. Presently, high-grade steel and iron, fortified against corrosion and wear, are the cornerstones of land roller production. These metals are frequently enveloped in specialized, enduring paints that brave the environmental onslaughts, ensuring longevity.

Spotlight on Mandako: A Modern Manufacturing Marvel

To gain a clearer understanding of the current manufacturing methods, let’s examine the case of the Mandako plant in Canada.

Mandako, a leader in the agricultural equipment industry, exemplifies modern manufacturing excellence. The plant employs state-of-the-art CNC machines, like the Mazak Quick Turn 250 MSY, which are renowned for their high performance and versatility. This particular model enhances productivity by allowing for multitasking—simultaneous milling and turning, which reduces the time taken to produce parts.

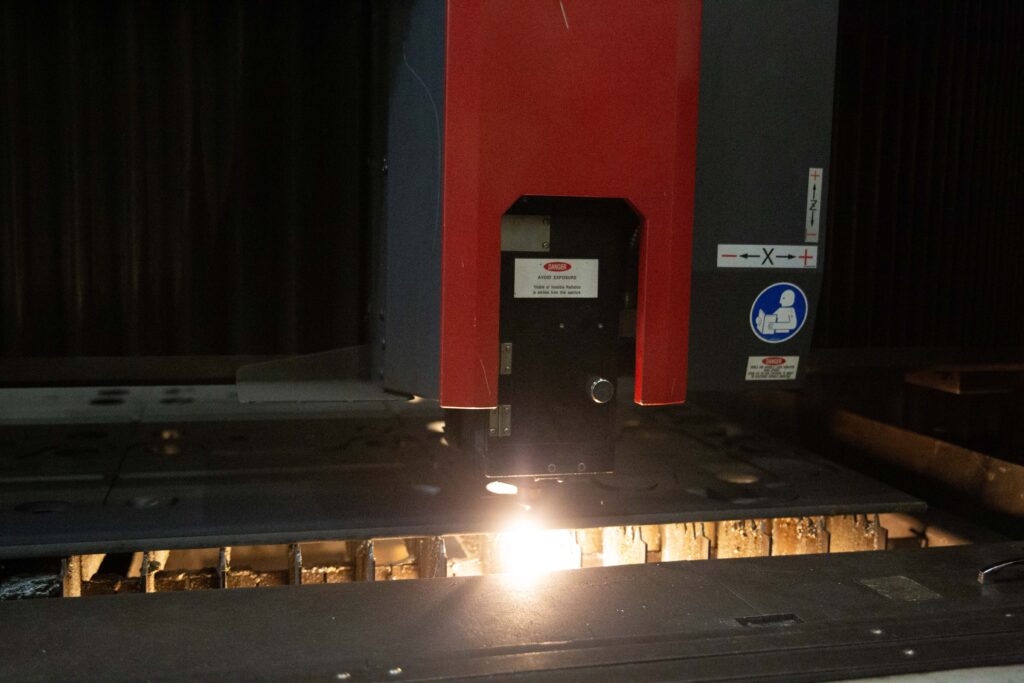

Advancements in Cutting and Welding Techniques

- The olden practice of saw cutting has been supplanted by modern methodologies like plasma and laser cutting in current production regimes. These advanced techniques are acclaimed for their precision, accelerating production timelines and achieving meticulous adherence to engineering blueprints.

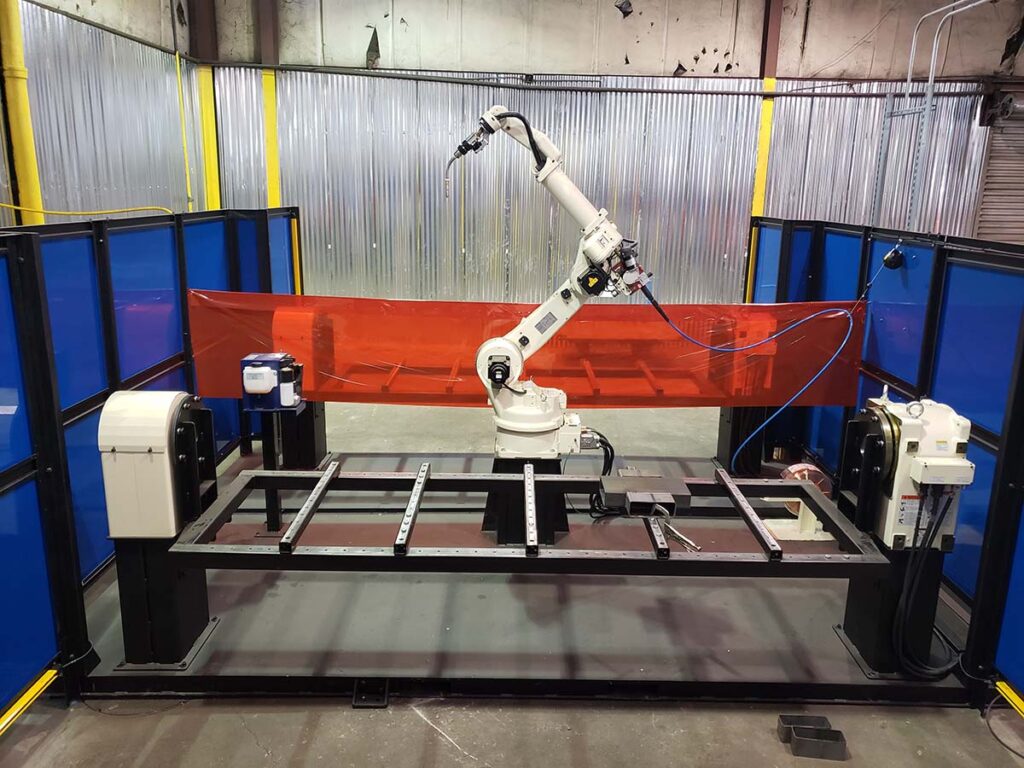

Precision Engineering at Mandako

The advent of robotic welding stations marks a significant evolution from traditional manual welding, particularly for repetitive tasks. These automated stations, driven by CNC technology, ensure uniformity in quality while bolstering manufacturing efficiency.

Another pivotal element in Mandako’s array of advanced technology is the Doosan DNM 750L vertical machining center. Celebrated for its precision and ability to manage large components, the DNM 750L plays a crucial role in crafting complex parts that adhere to rigorous quality benchmarks. This ensures impeccable assembly and boosts the functionality of the land rollers, maintaining Mandako’s reputation for excellence in agricultural machinery.

Enhancing Durability and Efficiency in Modern Land Rollers

The reliability of modern land rollers is further enhanced by the use of high-quality lubricants in all moving parts, reducing wear and tear and extending the machinery’s operational life.

Moreover, the thickness of the metal used in today’s rollers is optimized for maximum durability without compromising efficiency.

From Simplicity to Sophistication: The Evolution of Land Rollers

The transition from basic wooden and stone rollers to today’s advanced steel and iron models represents a significant advancement in agricultural equipment manufacturing. Mandako’s use of cutting-edge technologies and sturdy materials reflects an industry-wide shift toward more efficient, durable, and precise tools. This steady advancement is vital for improving land roller functionality and for enhancing sustainable practices and productivity in global agriculture.

FAQs:

- What are land rollers and why are they used in agriculture? Land rollers are agricultural tools used to even out the field, break soil clods, and enhance seed-to-soil contact. This results in a more uniform planting bed, crucial for optimizing crop emergence and growth.

- How have land rollers evolved from their ancient forms to modern designs? Initially, farmers used heavy stones or logs as land rollers. With the industrial revolution, materials like cast iron and later steel were introduced, improving durability and efficiency. Modern land rollers now feature adjustable widths and hydraulic mechanisms for greater flexibility and precision.

- What were the key innovations in land roller technology during the Industrial Revolution? During the Industrial Revolution, the introduction of steam-powered machinery and the use of cast iron significantly advanced agricultural tools, including land rollers. Innovations included designs with teeth or smooth surfaces, which helped meticulously compact the soil and conserve moisture.

- How has material science influenced the development of land rollers in the 20th century? The shift from cast iron to steel in the 20th century marked a significant development in land roller technology. Steel’s superior durability and operational efficiency allowed for the creation of land rollers with features like adjustable widths and hydraulic systems, catering to diverse agricultural needs.

- What modern technologies are employed in the manufacturing of land rollers today? Modern manufacturing techniques, such as CNC machining, plasma and laser cutting, and robotic welding, have revolutionized the production of land rollers. These technologies enhance precision, efficiency, and the overall durability of the equipment, exemplified by companies like Mandako.

Publication Date: 04 May 2024 Estimated Reading Time: 5 minutes