When autumn arrives, it’s crucial to prepare the soil for the upcoming season to secure a rich harvest. Your task is to reduce erosion risks and create conditions for retaining moisture and oxygen in the soil. Special equipment used during autumn soil treatment can improve its structure. Vertical processing, which we’ve previously discussed, is the best method. Farm discs and speed blades for loosening the soil will assist you in this process.

Types of Farm Discs

You can opt for classic farm discs or speed blades. The classic ones are more familiar and economical. Various types of reinforcement and special grades of steel are used to make them more durable. It’s important to choose discs manufactured with technology that prevents rapid dulling and deformation.

Characteristics of Speed Blades for Soil Processing

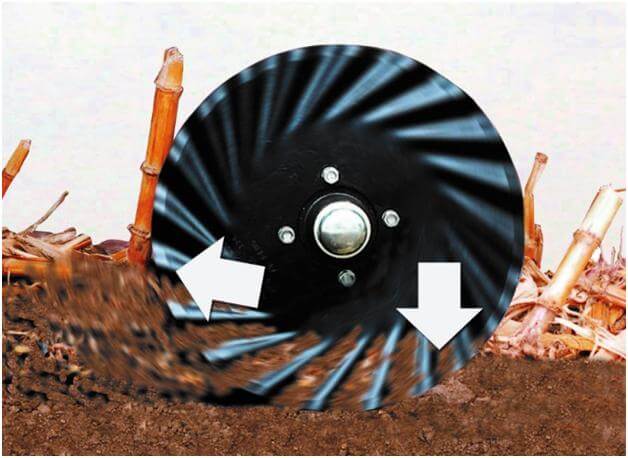

Speed blades are key components of soil processing machines that penetrate deeper due to their larger diameter and razor-sharp edges. They are ideal for large planting areas with significant residues, performing better than classic discs. We offer a 22-inch diameter blade, which is larger than a classic disc and made from a particularly durable grade of steel. This material choice resists quick wear and helps maintain the blade’s shape even during continuous use on hard soils. Additionally, our top seller, the samurai blade, features a 20-inch diameter and provides extremely precise cutting, making it excellent for handling hard residues.

We provide this general information for your familiarity. However, it’s best to consult a specialist who can help you choose the right equipment, be it a classic disc or a blade for deeper soil processing. You’ll receive answers to all your questions and recommendations during this consultation.

Choosing the Right Farm Discs and Speed Blades

Choosing the right farm discs and speed blades is crucial since every farm has its own soil type, terrain, plot size, and processing goals. If the soil is soft, a disc will suffice, but for more challenging soils, a speed blade is indispensable. It’s also important to match the equipment correctly: ensure that your cutting components are compatible with your existing plows, harrows, and disc harrows.

Soil Razor/Stickleback Blade (22″ Diameter)

Tips for Effective Soil Processing

Before starting and after finishing your work, it’s important to check the condition of the discs and blades to ensure they are not deformed and to sharpen them if necessary. Also, prepare the equipment you will attach them to by performing preventative maintenance and technical inspections.

Disc harrows, despite their simple usage, are quite complex and function as just one of the working units; they cannot be used alone. The frame with the harrow attaches to the tractor, which is either a specialized mounted or trailed equipment.

As you can see, checking and adjusting all these units can be time-consuming. It’s advisable to start preparations in the summer when you have more time, rather than at the last minute. Make sure to lubricate parts, and repair or replace components as necessary to avoid breakdowns during operation.

FAQs:

- How do I choose the right farm discs and speed blades for my soil? Choosing the right equipment depends on several factors such as soil type, terrain, plot size, and your specific processing goals. For softer soils, a standard disc might be sufficient. However, for tougher soil conditions, you may require speed blades that can penetrate deeper and handle large residues more effectively.

- What are the advantages of using speed blades over classic farm discs? Speed blades penetrate deeper into the soil due to their larger diameter and razor-sharp edges, making them ideal for large areas with significant residues. They are also made from durable steel that resists wear and maintains shape even under hard soil conditions, offering better performance compared to classic discs.

- Can I use classic farm discs on all types of soil? Classic farm discs are suitable for softer, less challenging soils and are more economical. However, they may not perform well on harder soils or in conditions with heavy residue. In such cases, speed blades or heavier equipment might be necessary.

- What should I check before and after using farm discs and speed blades? It’s essential to inspect the condition of the discs and blades for any signs of deformation or dullness. They should be sharpened if necessary. Also, prepare the machinery they will be attached to by conducting preventative maintenance and technical inspections to ensure everything functions properly during use.

- How do speed blades enhance soil preparation compared to classic discs? Speed blades are designed to penetrate deeper into the soil, thanks to their larger diameter and sharper edges. This makes them particularly effective on large plots with significant plant residues. The enhanced cutting ability of speed blades allows for more thorough soil processing, improving soil structure and readiness for planting, which can lead to better crop yields than what is typically achieved with classic discs.

Publication Date: 16 May 2024 Estimated Reading Time: 5 minutes